Are Lawnmower Blades Reverse Threaded? A Complete Guide

I still remember the first time I tried to change a lawnmower blade. It was a hot July day in Georgia. The humidity was thick enough to chew on. My old push mower had hit a hidden tree root. The cut was bad. The grass looked torn, not sliced. I dragged the mower out to the driveway.

With a socket wrench in hand, I leaned into the bolt with all my strength. It didn’t budge. I pulled harder. Nothing. My knuckles turned white. Sweat dripped into my eyes. I started to panic. Was I tightening it? Are lawnmower blades reverse threaded?

At the time, I had no real idea what I was doing.

Everything was a guess, and it cost me—I stripped the bolt head.. It was a nightmare. I learned a hard lesson that day. Knowing the thread direction matters. Knowing the thread direction saves time, protects your hands, and keeps your mower running properly.

Today, I fix mowers for fun. Over the years, I’ve helped neighbors all around my town and seen just about every mistake possible.

The goal here is to save you from that same frustration. This guide is for you. We will figure this out together. We will get that blade off safely. And we will get you back to a clean cut.

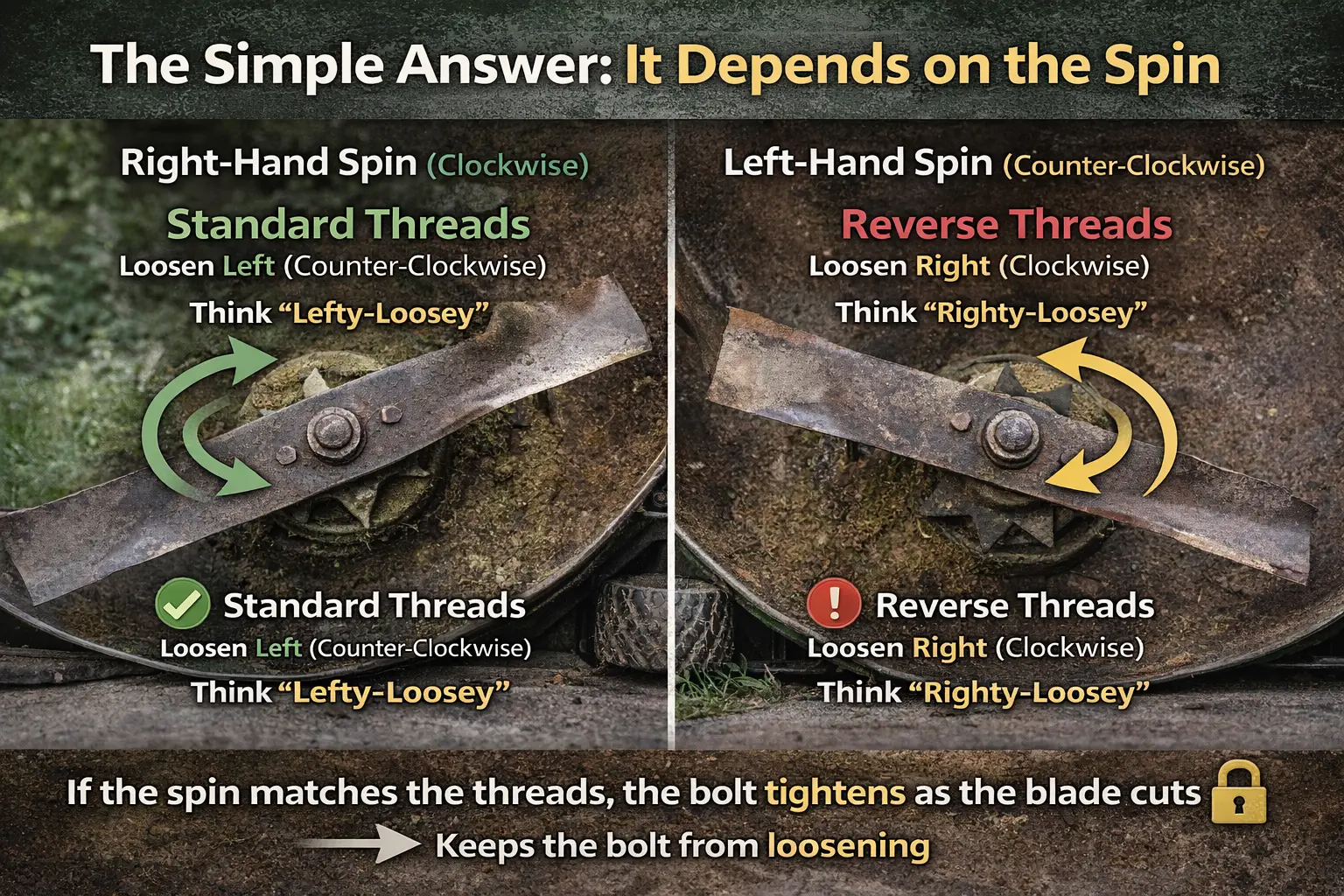

The Simple Answer: It Depends on the Spin

Most mowers are normal. But some will trick you. You need to know which one you have.

Here is the rule of thumb. It is all about how the blade spins.

- Right-Hand Spin (Clockwise): This is standard. The bolt has normal threads. You turn it left (counter-clockwise) to loosen. Think “Lefty-Loosey.”

- Left-Hand Spin (Counter-Clockwise): This is rare. The bolt has reverse threads. You turn it right (clockwise) to loosen. Think “Righty-Loosey.”

Why does this happen? It is physics. The manufacturer wants the bolt to stay tight. As the blade cuts grass, it hits resistance. This drag pushes against the spin.

If the bolt thread matches the spin, the drag tightens it. It is a self-locking design. It keeps the blade from flying off. That is a good thing. We want the blade to stay put.

So, look at the spin. That is your first clue.

Determining Your Mower’s Rotation Direction

You do not need to be a mechanic to find this out. You just need your eyes.

Check the Discharge Chute

This is the easiest way. Look at your mower deck. Find the hole where the grass shoots out.

- Rear Discharge: The chute is in the back. These usually spin clockwise.

- Side Discharge: Is the hole on the right? The blade likely spins clockwise. Is it on the left? It might spin the other way.

Imagine the grass leaving the deck. The blade throws it out. If the chute is on the right, the blade has to spin right to throw it there. It is like a pitcher throwing a ball.

Look at the Blade Edge

Tip the mower up. Make sure the spark plug wire is off. Look at the blade. It has a sharp edge and a dull edge.

- Sharp Edge Leads: The sharp part cuts the grass. It has to hit the grass first.

- Clockwise: If the sharp edge is on the right side as you look down, it spins right.

- Counter-Clockwise: If the sharp edge is on the left, it spins left.

Trace the path with your finger. Do not touch the sharp part. Just trace the air. Visualize the spin. It will click in your head.

Read the Sticker on the Deck

Manufacturers know we forget things. They often put a cheat sheet right on the mower.

- Look for a Decal: It is usually on top of the deck.

- Arrows: Look for a curved arrow. It shows the spin direction.

- Warnings: Sometimes the warning label tells you.

I once worked on a Honda. The sticker was covered in mud. I wiped it off with my thumb. There it was. A big yellow arrow. It saved me a lot of guessing. Always look for the sticker first.

Common US Mower Brands and Their Threads

I have used almost every brand out there. Here is what I usually see in American garages.

Toro

Toro is very popular here. I see them everywhere in the suburbs.

- Most Walk-Behinds: Standard thread. Turn left to loosen.

- Time Cutter: Usually standard.

- Exceptions: Always check the manual. But 99% of the time, it is lefty-loosey.

Honda

Honda engines run forever. Their mowers are great.

- Single Blade: Standard thread.

- Twin Blade (MicroCut): These have two blades stacked. They still use a standard thread bolt.

- Tip: The bolts can be very tight on Hondas. They use strong torque.

Craftsman

These are classic American mowers. Older ones are everywhere.

- Push Mowers: Standard thread.

- Riding Mowers: This gets tricky. Some decks have multiple blades.

- The Mandrel: The part that spins the blade. Check the pulley.

John Deere

Green and yellow. You know the look.

- Tractors: The blades usually spin clockwise. Standard threads.

- Zero Turns: Some have a reverse spin on one side.

- Why: To throw grass better. Check the specific bolt head.

Cub Cadet

I used one of these last week. It was a beast.

- The Deck: Most use standard threads.

- Blade Nut: Some use a nut, not a bolt. The rule is the same.

- Safety: Wear gloves. These blades are heavy.

Tools You Need to Remove the Blade

You cannot do this with your bare hands. You need the right tools.

The Socket Wrench

This is your best friend. Do not use pliers. You will strip the head.

- Size: Most US mowers use a 5/8 inch or 1/2 inch socket. Some use 9/16.

- Drive Size: Use a 1/2 inch drive ratchet. It is stronger. A 3/8 drive might snap.

- Length: A longer handle gives you more power. It makes the job easier.

The Breaker Bar

Sometimes a ratchet is not enough. The bolt is frozen.

- What is it: A long metal bar with a socket head. No ratchet mechanism.

- Leverage: It gives you huge torque.

- Use: Break the bolt loose with this. Then switch to the ratchet.

The “Block of Wood”

This is a pro tip. You need to stop the blade from spinning.

- Material: A scrap piece of 2×4 or 4×4.

- Placement: Wedge it between the blade and the deck wall.

- Safety: It keeps your hands away. It locks the blade solid.

Do not hold the blade with your hand. Even with gloves. If the wrench slips, you will get cut. The wood block is safer. It costs nothing. I keep one in my toolbox just for this.

Penetrating Oil

Rust is the enemy. It acts like glue.

- Brand: PB Blaster or WD-40 Specialist.

- Action: It soaks into the threads. It eats the rust.

- Time: Spray it on. Wait 15 minutes. Let it work.

I live in a humid area. Bolts rust fast here. I always spray them first. It saves me so much anger. It is worth the wait. Go drink some water while it soaks.

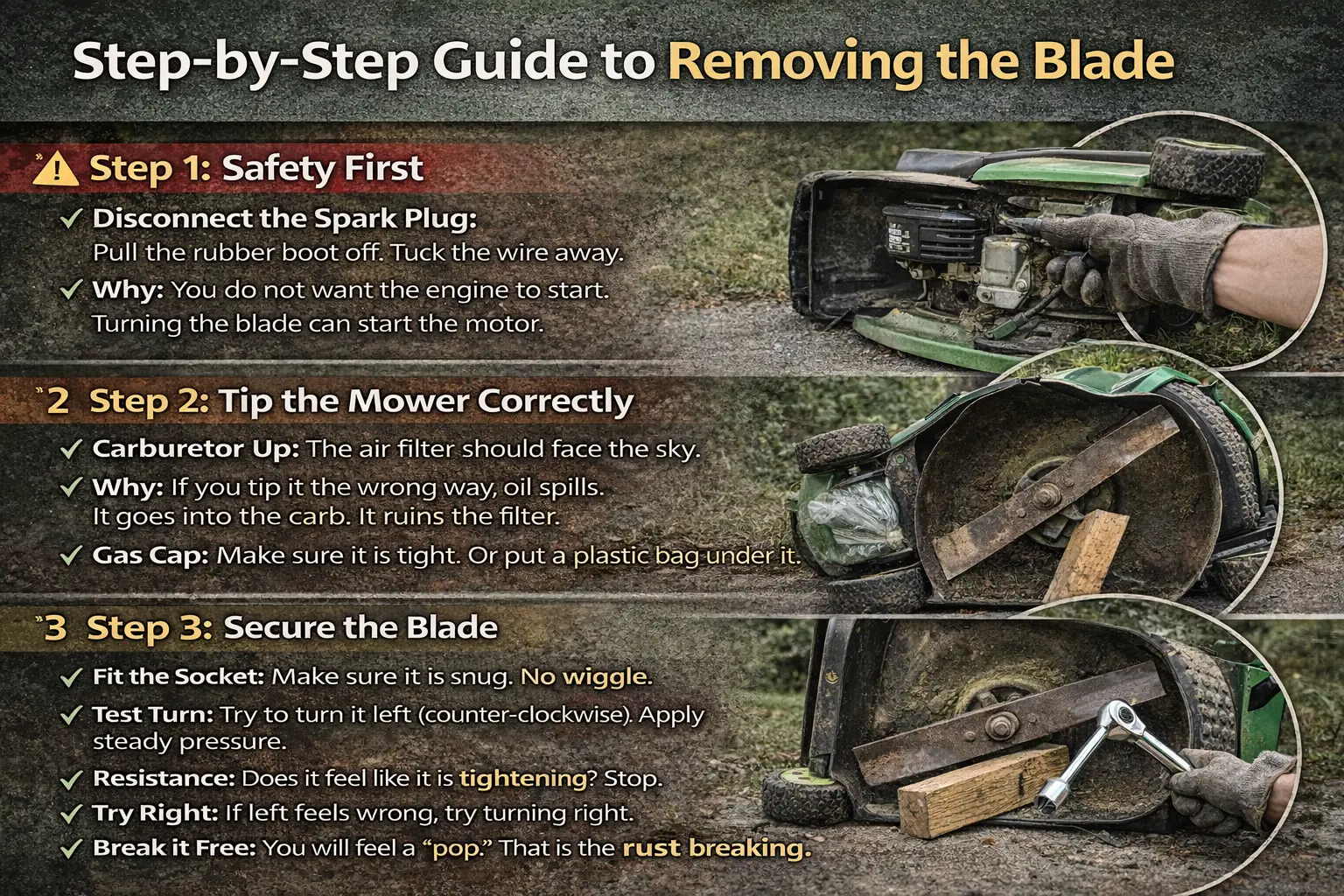

Step-by-Step Guide to Removing the Blade

Let’s do this safely. Follow these steps exactly.

Step 1: Safety First

Do not skip this. Seriously.

- Disconnect the Spark Plug: Pull the rubber boot off. Tuck the wire away.

- Why: You do not want the engine to start. Turning the blade can start the motor.

- Scary: It has happened. People lose fingers. Be safe.

Step 2: Tip the Mower Correctly

You need access to the bottom. But you cannot just flip it over.

- Carburetor Up: The air filter should face the sky.

- Why: If you tip it the wrong way, oil spills. It goes into the carb. It ruins the filter.

- Gas Cap: Make sure it is tight. Or put a plastic bag under it.

I once tipped a mower the wrong way. Oil went everywhere. It smoked like a freight train when I started it. My neighbors thought my house was on fire. Learn from my mistake. Keep the carb up.

Step 3: Secure the Blade

Now you are looking at the blade.

- Clean it: Brush off the caked-on grass. See the bolt clearly.

- Insert the Block: Wedge your wood block in.

- Direction: Place it so the blade hits the wood when you turn the bolt to loosen.

H3: Step 4: Loosen the Bolt

Here is the moment of truth.

- Fit the Socket: Make sure it is snug. No wiggle.

- Test Turn: Try to turn it left (counter-clockwise). Apply steady pressure.

- Resistance: Does it feel like it is tightening? Stop.

- Try Right: If left feels wrong, try turning right.

- Break it Free: You will feel a “pop.” That is the rust breaking.

Troubleshooting Stuck Bolts

Sometimes the bolt fights back. It happens. Do not give up.

Use More Leverage

If you are small like me, you need help.

- Cheater Pipe: Slide a metal pipe over your wrench handle.

- Physics: A longer handle multiplies your force.

- Caution: Go slow. You can snap the bolt head off.

Apply Heat

Heat expands metal. It breaks the rust bond.

- Tool: A heat gun is best. A propane torch is risky near gas.

- Target: Heat the bolt head. Not the blade.

- Duration: Heat it for a minute. Then try turning.

Be careful with fire. There is gas and oil nearby. I prefer a heat gun. It is safer. It takes longer but works well.

Impact Wrench

This is the nuclear option.

- Power: It uses quick bursts of force.

- Vibration: The rattling helps break the rust.

- Electric: Battery impact guns are great for this.

- Caution: Make sure you are turning the right way. An impact gun will snap a bolt instantly if you go the wrong way.

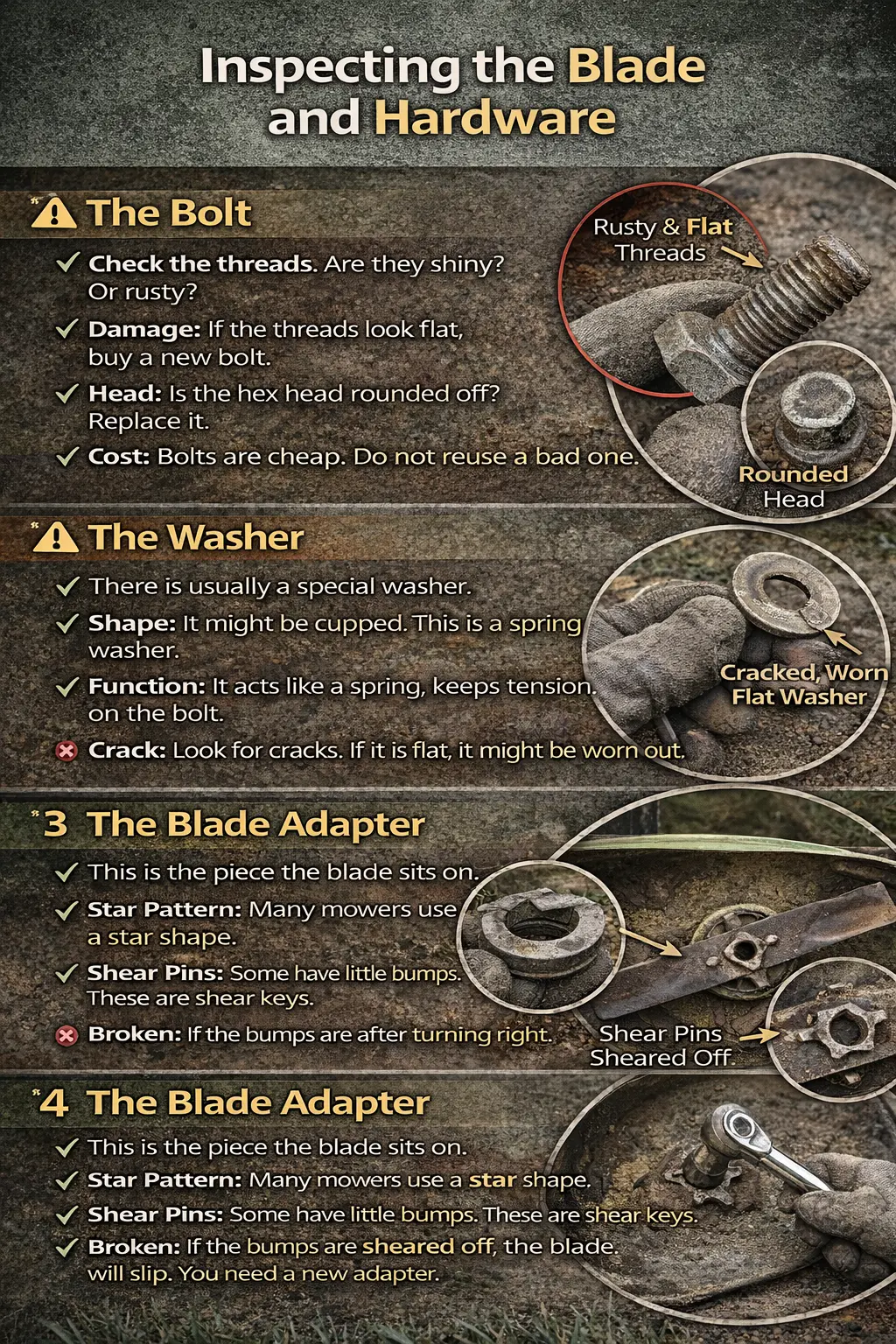

Inspecting the Blade and Hardware

The blade is off. Now look at the parts.

The Bolt

Check the threads. Are they shiny? Or rusty?

- Damage: If the threads look flat, buy a new bolt.

- Head: Is the hex head rounded off? Replace it.

- Cost: Bolts are cheap. Do not reuse a bad one.

The Washer

There is usually a special washer.

- Shape: It might be cupped. This is a spring washer.

- Function: It acts like a spring. It keeps tension on the bolt.

- Crack: Look for cracks. If it is flat, it might be worn out.

The Blade Adapter

This is the piece the blade sits on.

- Star Pattern: Many mowers use a star shape.

- Shear Pins: Some have little bumps. These are shear keys.

- Broken: If the bumps are sheared off, the blade will slip. You need a new adapter.

I see this a lot. The owner hit a rock. The bolt is tight. But the blade spins freely. The adapter pins are gone. It did its job. It saved the engine. But now you need a part.

Sharpening vs. Replacing

Do you need a new blade? Or just a file?

When to Sharpen

- Dull Edge: If it is just round, sharpen it.

- Small Nicks: Tiny chips are fine. File them out.

- Frequency: Sharpen twice a season. It helps the grass heal.

When to Replace

- Bent: Never use a bent blade. It shakes the mower. It kills bearings.

- Cracked: Look near the center hole. A crack is dangerous.

- Thin: Sand wears the metal. If the wing is paper-thin, toss it.

A new blade is about $20. It is not worth the risk. If it looks bad, get a new one. Your grass will thank you.

Installing the New Blade

Putting it back is easy. But pay attention.

Orientation is Key

This is the biggest mistake people make.

- Upside Down: People put the blade on upside down.

- Result: It will not cut. It will just beat the grass.

- Visual: The “wings” or “fins” must point UP towards the deck.

- Markings: Look for “Bottom” or “Grass Side” stamped on the metal.

One time, I managed to mow half my lawn with the blade installed upside down.

The results looked terrible, and it didn’t take long to realize my mistake—definitely a humbling moment. Check the wings. Wings go up.

Tightening the Bolt

- Hand Tight: Thread it in by hand first. Do not cross-thread it.

- Block: Move the wood block. Put it on the other side now.

- Tighten: Turn the bolt clockwise (for standard threads).

Torque Specs

How tight is tight enough?

- Check Manual: It will say something like “40 ft-lbs.”

- Torque Wrench: If you have one, use it.

- Feel: If not, get it snug. Then give it another quarter turn.

- Do Not Overtighten: You can stretch the bolt.

Different Types of Blades

Not all blades are the same. Pick the right one for your yard.

High-Lift Blades

These have big wings.

- Airflow: They create a lot of suction.

- Bagging: Best for bagging grass. It shoots it up the chute.

- Energy: They use more engine power.

Mulching Blades

These look wavy.

- Design: They cut the grass multiple times.

- Nutrients: The tiny pieces fall back into the soil.

- Environment: It is free fertilizer. I love mulching.

Low-Lift Blades

These are flat.

- Dust: Good for dry, sandy soil.

- Safety: They throw less dust and rocks.

- Regions: Popular in the Southwest US.

Regional Advice for US Lawns

Where you live changes how you mow.

Florida and the Southeast

It is wet here. Grass is thick. St. Augustine grass is tough.

- Blade Choice: Use a high-lift blade. You need suction.

- Maintenance: Check for rust often. The humidity is brutal.

- Cleaning: Scrape the deck after every mow. Wet grass turns to concrete.

The Midwest

You have cool-season grasses like Fescue and Bluegrass.

- Seasons: You have a long winter.

- Storage: Remove the blade in November. Clean the mount. Grease it.

- Spring: Put a sharp blade on in April. The first cut is important.

The Southwest

It is dry and rocky.

- Blade Wear: Sand acts like sandpaper. Your blade will dull fast.

- Check: Look at the blade every month.

- Lift: Use low-lift blades to reduce dust clouds.

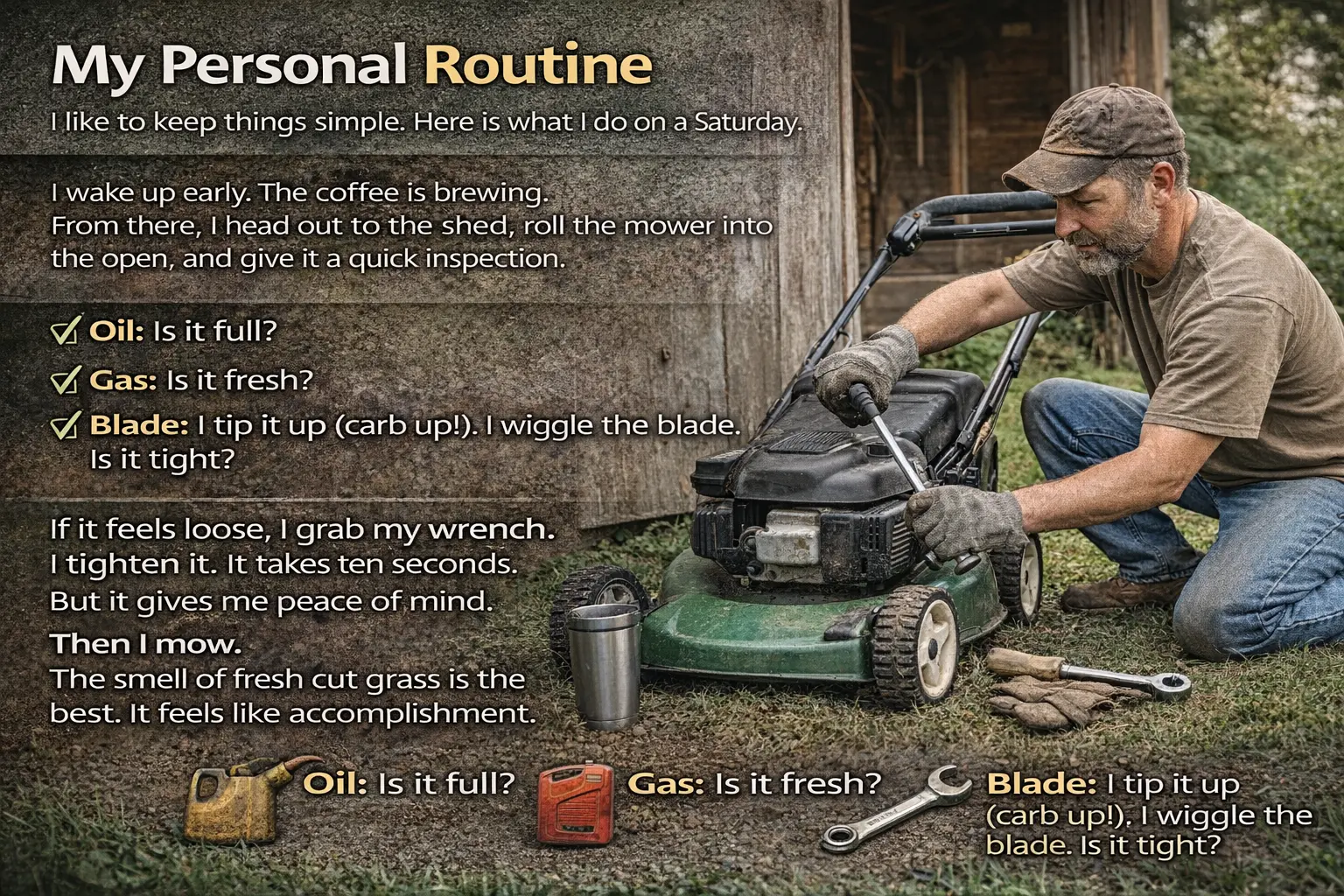

My Personal Routine

I like to keep things simple. Here is what I do on a Saturday.

I wake up early. The coffee is brewing. From there, I head out to the shed, roll the mower into the open, and give it a quick inspection.

- Oil: Is it full?

- Gas: Is it fresh?

- Blade: I tip it up (carb up!). I wiggle the blade. Is it tight?

If it feels loose, I grab my wrench. I tighten it. It takes ten seconds. But it gives me peace of mind. Then I mow. The smell of fresh cut grass is the best. It feels like accomplishment.

FAQ: Quick Answers

Here are questions I get asked at the hardware store.

Why does my mower vibrate so much?

It is usually the blade. It might be unbalanced. Or bent. Or loose.

- Fix: Take it off. Balance it on a nail. Does one side dip? File that side.

Can I reuse the blade bolt?

Yes, usually. But inspect it.

- Threads: If they look chewed up, toss it.

- Head: If the socket slips, replace it.

- Cheap Insurance: A new bolt is $3. An engine shaft is $200.

How do I know if my blade is dull?

Look at the grass tips.

- Brown Tips: After you mow, wait a day. Are the tips brown and ragged?

- Torn: That means the grass was torn, not cut.

- Sharp: A sharp blade leaves a clean, green cut.

My bolt spins but won’t come out. What now?

This is bad.

- Stripped: You stripped the threads in the spindle.

- Repair: You might need a Tap and Die set. Or a new spindle assembly.

- Professional: This might be a job for the shop.

Conclusion

So, are lawnmower blades reverse threaded? usually not. But sometimes yes.

It is a simple question with a “it depends” answer. But now you know how to look. Now you know how to check the chute, understand the blade’s rotation, and take control of the job with confidence.

Don’t let a stuck bolt ruin your weekend. Get the right tools. Use the wood block. Be patient with the rust. And always, always disconnect that spark plug.

Mowing the lawn should be relaxing. It is your time outside. It is satisfying. Keep your blade sharp and secure. Your lawn will look better. And you will feel like a pro.

Happy mowing, friends. Stay safe out there.

Rear More: Should You Change Lawnmower